Applications

Home – Applications

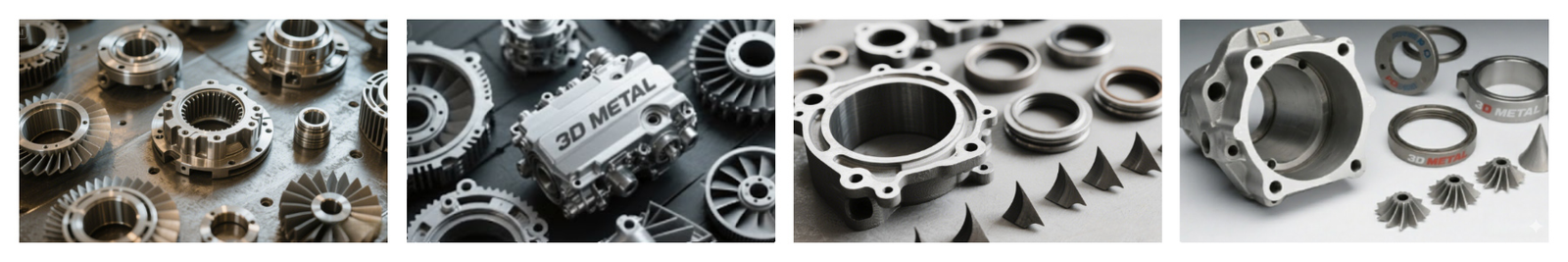

AEROSPACE

ENGINE CASINGS, RINGS, & VANES

These non-rotating critical components must function in extremely high temperatures while upholding their strength. They are particularly crucial in high-performance jet engines and industrial gas turbines, where they are subjected to continuous stress and intense heat. In these applications, the components’ ability to maintain their structural integrity is essential for safe and efficient operation.

FEATURED MATERIALS

INCONEL 718

Advanced Precipitation-Hardened Nickel-Based Superalloy for Extreme Environments This γ’-strengthened nickel-chromium superalloy leverages advanced precipitation hardening mechanisms to deliver sustained high-temperature performance (700–1000°C), combining specific strength three times higher than titanium alloys with density-optimized light weighting and multi-environment corrosion immunity, redefining material limits for next-generation propulsion and energy systems.

HA188

The material exhibits outstanding high-temperature strength up to 900°C, coupled with superior oxidation and corrosion resistance in extreme environments. This combination of properties ensures exceptional durability and reliability in applications subjected to intense heat and corrosive conditions.

STRUCTURAL LANDING GEARS

Customers require materials that can reliably withstand stresses induced under severe conditions. We offer a range of materials key to landing gear applications.

FEATURED MATERIALS

18Ni300 (1.2709, M300)

This steel exhibits high hardenability and strength, coupled with good ductility and toughness in heavy sections.

AIRFRAME FASTENERS

Fasteners contribute to weight, which is critical for aircraft given the importance of the strength-to-weight ratio. Quality remains essential in mission-critical environments characterized by temperature extremes, high pressures, mechanical stresses, load-bearing demands, and corrosion resistance requirements.

FEATURED MATERIALS

TI 6AL-4V

This fully heat-treatable workhorse alloy is designed to perform reliably at temperatures up to 350°C, offering a unique combination of strength, light weight, and superior corrosion resistance.

INCONEL 718

A precipitation hardenable nickel-base alloy exhibits exceptionally high yield strength, tensile strength, and creep-rupture resistance at temperatures up to 700-1000°C, specifically engineered for superior fatigue resistance under extreme operating conditions.

ENGINE MOUNTS

Attaches to the wing and transfers the thrust forces generated under extreme operating conditions.

FEATURED MATERIALS

INCONEL 718

Engineered to deliver breakthrough mechanical performance, this nickel-based superalloy combines unparalleled yield strength, ultimate tensile capacity, and creep-rupture resistance across extreme temperature ranges, while maintaining exceptional welding compatibility and multi-environment corrosion resilience.